OUR SERVICES

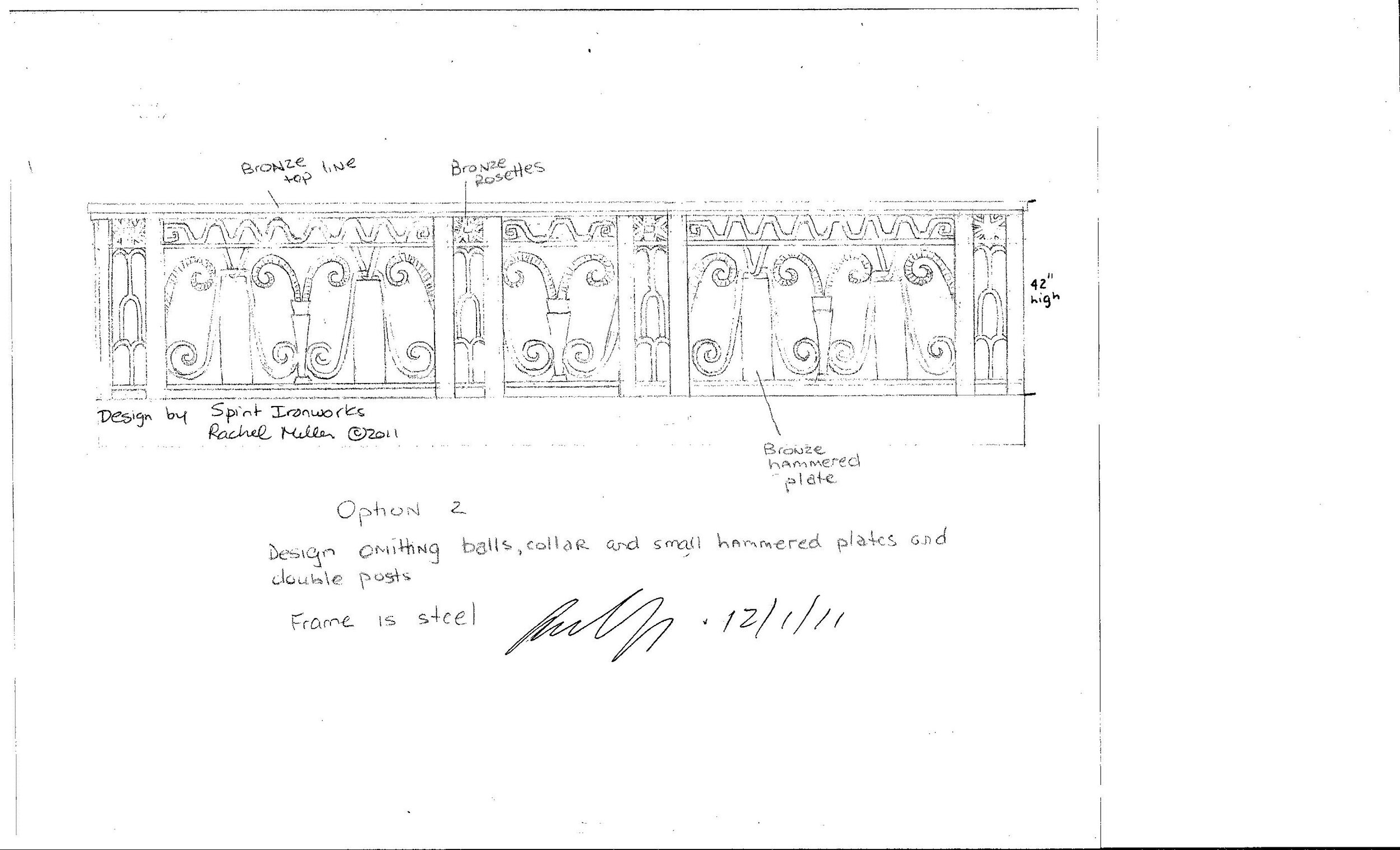

Design and Project Management

This is a collaborative process between the client and our company. The designer will meet with the client to discuss their needs, budget, and assess the environment in which the finished metalwork will be installed. The design process can be simple or involved depending on the complexity of the proposed project. It is important for the designer to consider many circumstances that will affect the finished product during the designing phase; some of these factors include building codes, safety/security issues, environmental exposure, type of metal chosen, time constraints, and availability of materials. Our in-house designers are experts in navigating through these issues all the while adhering to the client's desires. In many cases, the design can begin with a simple sketch and evolves into a full-scale Auto Cad drawing of the project for the client's approval. We can also produce shop drawings for architects/contractor's review and approval.

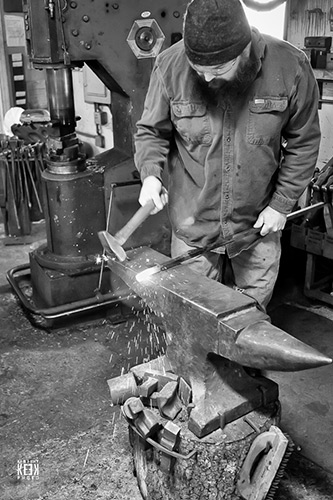

Blacksmithing/Custom Forging

Most work created by Spirit Ironworks involves time at the blacksmith's forge. To forge metal, it must first be heated to incandescent temperatures; it is then shaped using the impact of a hand hammer, or powered forging machine. An established blacksmith shop such as ours has accumulated hundreds, if not thousands of custom-made tools for forging metal. The design possibilities of forged metal are virtually limitless. To a blacksmith, metal becomes like a piece of clay that when heated, can be shaped in a myriad of ways. This is a highly skilled craft that takes years of training and practice to master. We are capable of forging copper, brass, bronze, nickel, Monel, aluminum, steel, and genuine wrought iron among others.

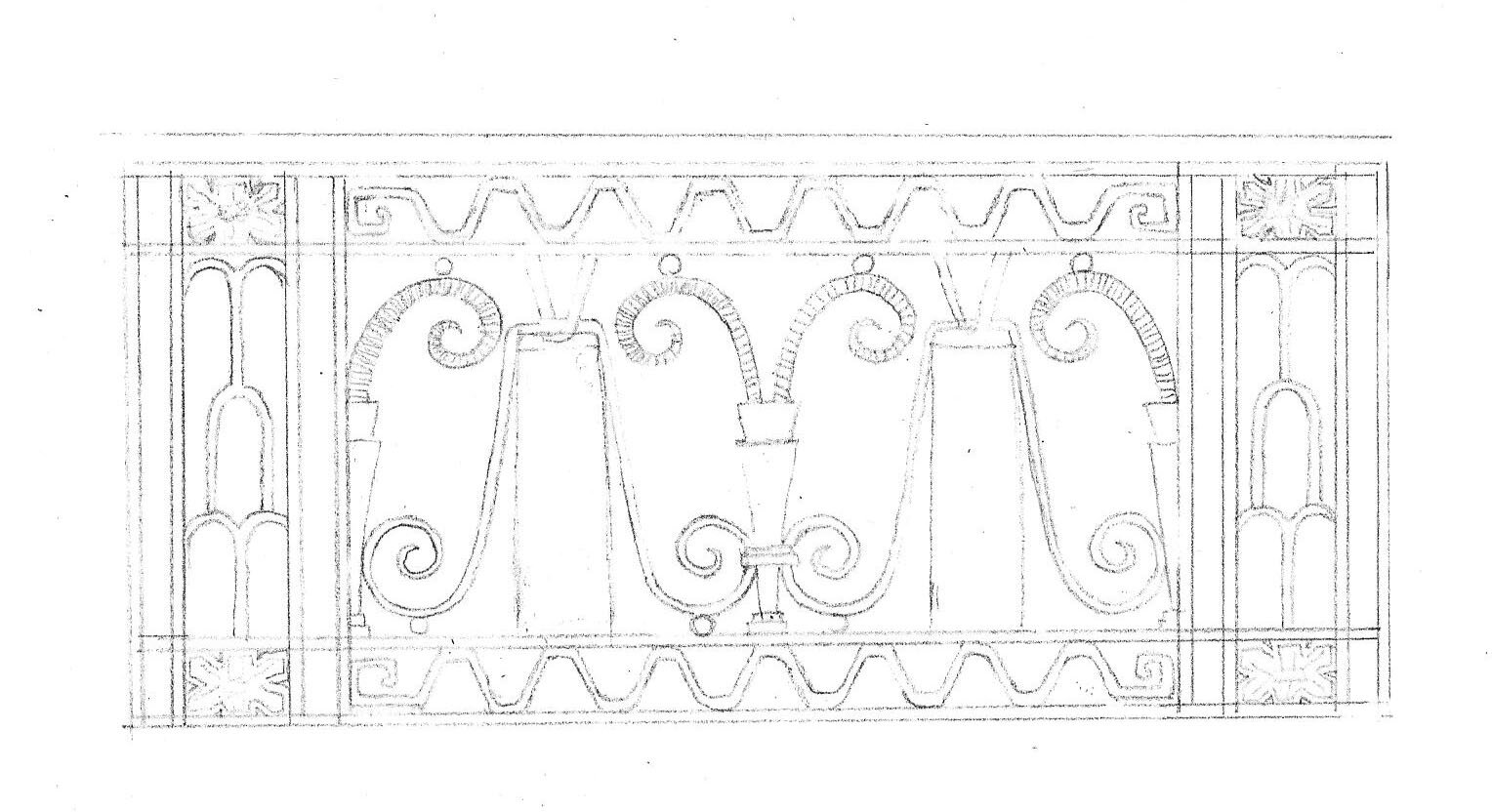

Custom Scrollwork

We specialize in creating custom scrollwork for use in historical restoration and ornamental metalwork. We can expertly replicate existing scrolls from samples, images, and drawings. Our staff is experienced in sourcing hard to find profiles and materials needed to make custom scrollwork. We also assist with joinery including rivets, collars, pins, screws, mortise and tenon, and of course, electric welding.

Metalwork Restoration

We are experts in restoring and replicating antique and historical metalwork for land-marked, and non land-marked properties. We can repair ironwork to National Park Service standards using genuine wrought iron and historically accurate techniques. We can also take existing antique ironwork and modify/restore it to work with the current function of the structure. Generally, the restoration process begins with assessing the damaged ironwork, cataloging and removing the piece(s) from site, cleaning, replacing/repairing, refinishing, and reinstalling the finished product. We are members of the New York City Landmarks Preservation Commission and are committed to upholding the historical integrity in every one of our restoration projects.

Public Sculpture/Art Fabrication

Our company has built and installed several large scale public sculptures. We are capable in all phases from concept, design, construction, finishing, and installation. We have collaborated with many community organizations to create designs that would enrich and enhance their public space. In addition to designing and building our own art work, we have done extensive metalwork for many artists including the world-renowned Jeff Koons.

Faux Finishes Hand Applied Patinas, Surface Textures

Our company adheres to the highest standards in metal finishing. This includes the "metalizing" of all exterior ironwork susceptible to rust. The process of "metalizing" is the application of a flame sprayed zinc coating which physically bonds to the material, protecting the ironwork by keeping it corrosion free for decades. We also offer custom high-grade paint, powder coating, chemical and natural patinas, gilding, as well as hand applied faux finishes.

Custom Hardware

We are experts in creating authentic and artistic hardware in a variety of materials. We can replicate and repair existing hardware on historical structures undergoing restoration. Some of our former projects include the reproduction of 17th century strap-hinges for one of the oldest homes on Long Island, and the replication of authentic hand-forged Monel hardware for a historic Jazz-aged estate located on Long Island's "gold-coast"

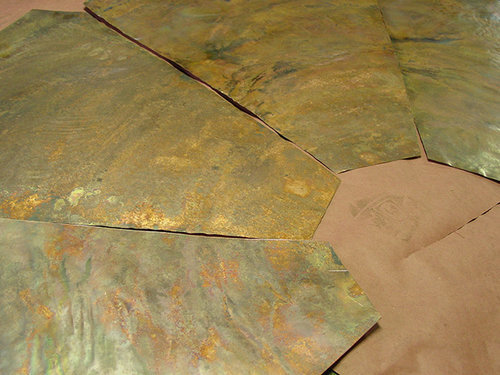

Hammered Copper, Bronze, Brass Sheet Metal Work

We are experts in producing uniquely textured sheet metal for both ornamental and functional applications. Whether copper, brass, zinc, or bronze, we can produce a custom texture and finish that will meet our client’s specifications. In addition to our textures and finishes, we also bend, cut, fold and form the piece(s) to create functional items such as canopies, range hoods, and counter tops.

For more options, please visit our Custom Hammered Metals Website>

A Look Inside Our Workshop

There is much that goes into every project we build that our clients never see. Here is a behind the scenes glimpse into our world.