OUR PROCESSES

Collars

Collar joinery is a commonly used method in blacksmithing. Attaching pieces of metal together by use of a collar can often dress up otherwise bland metalwork. The process begins with heating a strip of metal and wrapping it around the parts to be joined using various tools. Collars can be both decorative and functional. These can be made in a wide variety of shapes, profiles, or contrasting metals. They can also be used to cover welds or fasteners giving the finished item a decorative look.

Electric Welding

When we hear the term welding it is generally understood to mean MIG, TIG, or ARC welding. Each of these processes involve using an electric arc to melt the base metal and then filler metal is added. This creates an extremely strong metallic connection between the parts. In today's world, most metalwork is joined using one of these three electrical processes. Welding has become an art form in and of itself, creating much intrigue within tradespeople and novices alike. In ornamental work, welds are generally ground smooth or concealed as unfinished welds are viewed as unsightly. Creating clean welds takes practice and experience to master.

Forge Welding

Forge welding is the oldest of all the welding processes and can be traced back to the beginning of the Iron Age. When properly prepared, pieces of metal can be joined by heating them in a fire to near melting temperatures and then hammering them together on the anvil; this process, known as forge, or fire welding involves skill, proper timing, and dexterity. Forge welding is versatile, being able to join a host of similar and dissimilar metals. Visually, a forge welded joint is more fluid and naturalistic than what is achieved with electric welding. For certain kinds of work such as strap hinges, decorative chain, and other ornamental objects, the traditional method of forge welding is the most efficient way to go.

Gold Leafing

The craft of gold leafing can be traced back over 4,00 years to Northern Africa. To put it simply, gold leafing is the adornment of a piece of material through the application of gold foil onto its surface. Gold leaf is produced by hammering gold into extremely thin sheets; so thin in fact, that the lightest breeze would carry away a loose piece. The leafing process begins by painting a base coat of yellow or red ochre onto the metal. Sizing is then applied to adhere the gold leaf to the surface. Once the sizing is set, 23k gold leaf is meticulously hand applied to the surface and smoothed using custom gilding brushes. This is a pain staking process that requires both patience and attention to detail.

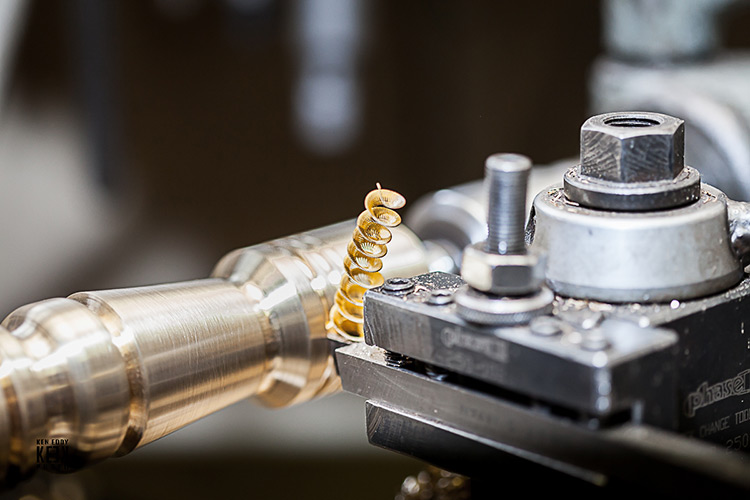

Lathe Turning

The lathe is the most fundamental of machine tools. It is used to make cylindrical parts of every possible description. It is used in ornamental ironwork to make one off custom finials, balls, urns and similar decorative elements. It can also be used to accurately drill and trim parts used in all kinds of wrought iron work. Decorative parts made on the lathe can be duplicated by making a die. The die is made by forging two red hot blocks of steel around the cold steel blank. These blocks are hardened and can be used to form the same part repeatedly.

Mortise and Tenon

Mortise and tenon is a traditional joinery method that can be traced back thousands of years in woodwork. This attachment method is often used in blacksmithing. To create this type of joint, a hole is punched in one piece of metal to create the mortise; then the corresponding tenon is shouldered and forged to size to fit the hole. The tenon is then trimmed to length and inserted in the mortise. At this point, the end of the tenon is peened over like a rivet which locks the mortise bar against the shoulder of the tenon. Using this technique, joinery can become decorative elements adding interest and visual impact to the work.

Metal fabrication for historical restoration. Replicating existing 1906 rosette to use in new custom decorative steel security gate.